- Home

- Products

- Bottom Feed Vibroflot

- 6 Bar Bvem Bottom Feed Vibroflot System 1800 Rpm

6 Bar Bvem Bottom Feed Vibroflot System 1800 Rpm

bottom feed vibroflotation method

bottom feed bottom feed vibro flotation method

bottom feed vibro flotation technique

Place of Origin: CHINA

Brand Name: BVEM

Certification: ISO 9001:2015

Model Number: BJZC-BFS-400-180

Product Details

Payment & Shipping Terms

Product Description:

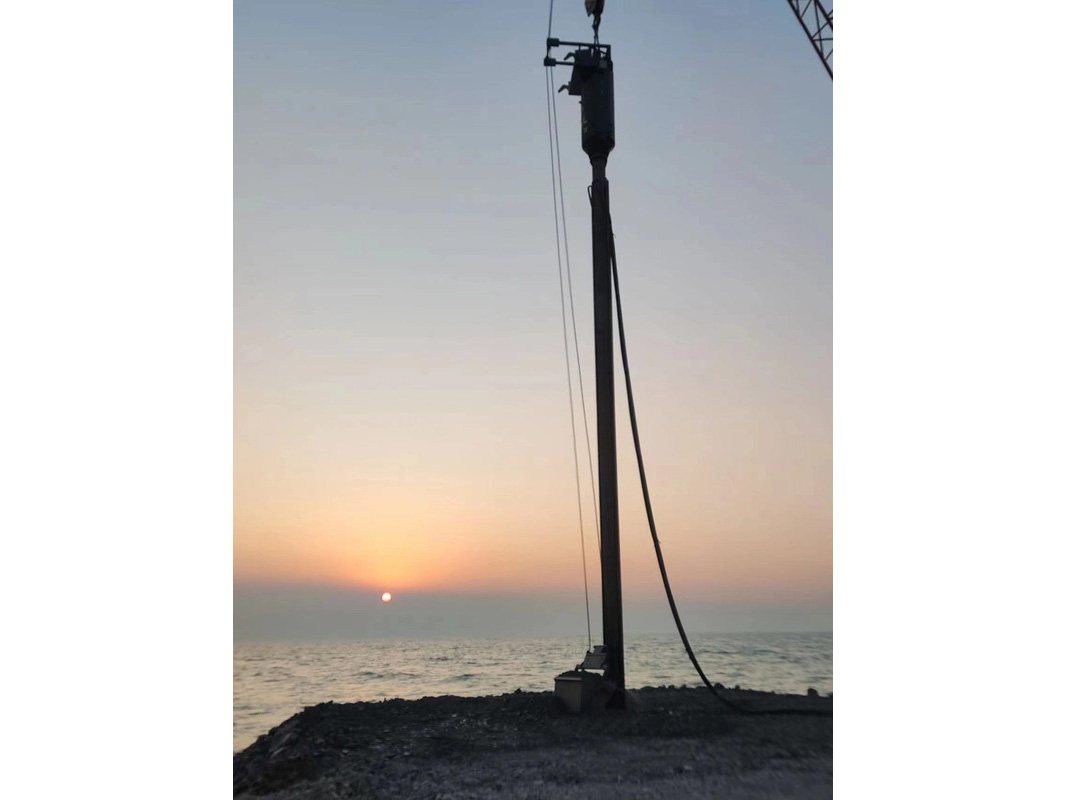

BVEM Bottom Feed Vibroflot System Applied in Reclamation Island Area including Large Water Amount

Bottom Feed Vibroflot is a stone column pile driver with an Inverter Drive control mode and Circulating Water Cooling cooling mode. It is made of high-quality stainless steel, and it can work with a frequency of 50/60Hz. The Bottom Feed Vibroflot is designed to efficiently drive stone columns into the ground, making it an ideal tool for pile foundation construction.

The Bottom Feed Vibroflot is the most efficient pile driver, capable of driving stone columns into the ground quickly and safely. It has an advanced control system that allows for precise operation and can be easily adjusted to meet different types of pile foundation requirements. The stainless steel construction ensures reliability and durability, while the circulating water cooling system helps to keep the machine cool while in use.

The Bottom Feed Vibroflot is an excellent choice for pile foundation construction, offering superior performance and reliability. It is easy to operate and maintain, and it is also highly efficient, making it an ideal choice for any construction or engineering project.

Technical Parameters:

| BVEM Bottom Feed Electrical Vibroflot Spec. | |

|---|---|

| Type | BJZC-BFS-400-180 |

| Power(kW) | 180 |

| Voltage(V) | 380 |

| Frequency(Hz) | 50 |

| Rotation speed(rpm) | 1200-1800 |

| Working pile diameter (mm) | 900-1200 |

| System pressure(bar) | 6 |

| Vibration force(kN) | 200-300 |

| Hopper volume(m³) | 1.2 |

| Pipe diameter(mm) | DN340 |

| Control type | Inverter Control |

| Cooling-down method | Circulating water cooling |

| Air flow rate(m³/min) | 10 |

| Vibrator size L/W/H(mm) | 2600×600×700 |

| The bin size L/W/H(mm) | 4800×1300×(1300-1500) |

| Extension tube size L/W/H(mm) | 12000×300×600 |

| Weight (Standard part+Extension tube) (ton) | 9+3×n |

BVEM company profile (Beijing vibroflotation engineer machinery co.,ltd)

Beijing Vibroflotation Engineering Machinery Co. Ltd (BVEM) is a subsidiary of Beijing Vibroflotation Engineering Co. Ltd. , a leading company in China’s vibroflotation industry. As the domestic leader of the complete sets of vibroflot equipment development and production, BVEM has the largest domestic production line of electric vibroflot. She is the chief-editor of the Chinese electric vibroflot manufacturing standard, is also a Chinese brand facing the world to provide the high quality complete sets of vibroflot equipment for users all over the world.

The business covers a wide range of engineering construction fields including power, transportation, petrochemical. Port, airport and housing construction. Outside of China, BVEM’s business has been extend to more than 30 countries worldwide, and it is an important participant in vibroflotation construction projects all over the world.

Overview of Bottom feed vibroflotation

Bottom feed vibroflotation method : during the construction of Vibroflotation Gravel Pile or vibroflotation sand pile, the filling material directly reaches the real-time hole bottom position of pile making through the filling pipe attached to the vibroflotation equipment, and the gravel pile or sand pile is carried out. The emergence and application of bottom feed vibroflotation method further expands the applicable scope of vibroflotation method in various projects.

BVEM Bottom Feed Vibroflotation device system applied in reclamation island area including large water amount

The site condition of project is the land after reclamation, which has naturally subsided for about two years. There is significant water accumulation on the surface, with a depth of ten meters below the surface being silty sand and a saturated silt layer. Later, a sandy soil 1.5 meters high from the horizontal is buried on the ground.

The unique characteristics of bottom feed vibroflotation device in soft foundation treatment, such as smooth and precise filling, have been outstanding in this test. The speed of each pile (about 11m) in 25 minutes has greatly improved the construction efficiency.

English

English Español

Español Français

Français Português

Português العربية

العربية