Beijing Vibroflotation Engineering Machinery Co., Ltd. (BVEM) started from a special R&D team worked for a vibroflot strategic localization project and organized by Ministry of Water Resources and Hydro-power.

Overview: Gravel or backfill sand is filled from top of borehole.

It's wildly commonly used vibroflotation equipment.

Used for vibro compaction and vibro replacement construction in general condition.

Economy and efficient vibro construction method.

Overview: Gravel or backfill sand is filled from top of borehole.

The most commonly used vibroflotation equipment.

Used for vibro compaction and vibro replacement construction in general condition.

Economy and efficient vibro construction method.

Characteristics: The vibroflot barrel and the motor housing are made of high strength forged steel.

The motor coil adopts high temperature aging film envelop, long service life and good insulation effect.

Unique circulating water cooled motor structure, good heat dissipation with high efficiency.

Both vibroflot and motor are imported with FAG original bearing.

Double-deck vibrating head design with good resistance, easy to replace.

Unique bearing oil lubrication, further improve bearing life.

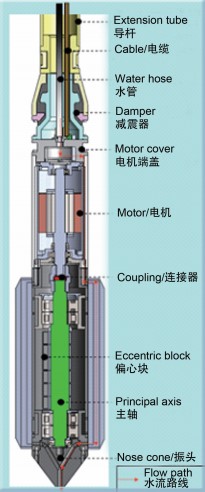

The Vibroflot is a slim vibrator which is vertically lowered into the soil, using water pressure and gravity. The Vibroflot is used for compaction and to stabilize loose grainy soil by vibrating. By extending the vibrator with follower tubes, greater depths can be reached.

A Vibroflot can be used for ground improvement in the following ways:

● Compaction: soil is added from the top of the vibrolans

● By adding other material e.g. gravel.

● By creating stone columns. Gravel is added from the bottom of the vibrolans. This increases the bearing capacity of the soil. Foundation settlements, seismic subsidence and liquefaction are being prevented.

Because the compacted soil becomes more compact, a funnel arises at the surface. By adding soil during the retracting movement – the vibrovlot is started and stopped at predetermined times - a compact and stable soil arises.

The vibrating movement of the Vibroflot is generated by the hydraulic powered eccenter in the nose of the Vibroflot. By pressing water from the bottom and the sides of the Vibroflot, it can be lowered to the desired depth easily.

A Vibroflot is suspended free hanging from a crawler crane or leader guided in a rig. It can also be driven in and by an excavator. Real-time data from a single or tandem set up is displayed on a monitor and can be downloaded at any time to support job reports.

More project case can be found here >>

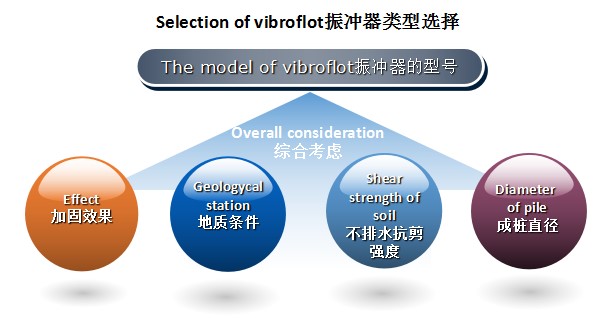

BVEM provides two models Vibroflot, that are more or less identical in terms of dimensions. The difference is determined by the eccentric moment. Both models can be assembled in a modular way. Various accessories are available for the different applications. For more information about this specific product, we would like to refer you to the sales department.

A foundation treatment method by joint action of horizontal vibration and high pressure water shock to:

Compact the loose sand layer or formed in soft soil of gravel column to compose the composite foundation with original soil together.

Vibroflotation process.

Vibro replacement.

Vibro compaction.

Vibro-composite foundation.

In-site test.

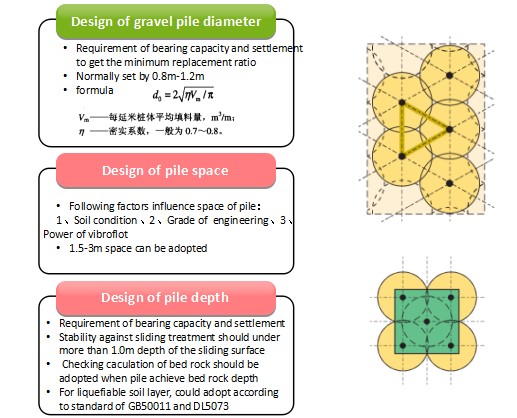

Replacement rate.

Stress ratio.

Equivalent column diameter.

Compaction current.

Compacting cycle increment.

Compaction time.

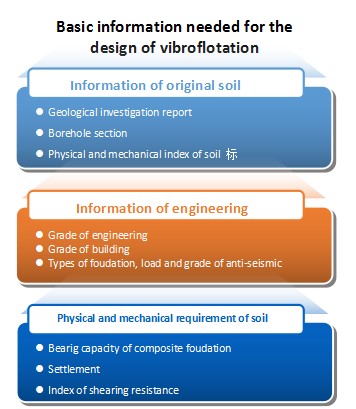

Usually the soil condition are describe in a soil investigation report. If the properties of soil cannot fulfil the requirements set by the proposed loading conditions, vibro technique offers a economical solution for the ground improvement. It can be carried to almost any depth.

The core element of vibroflot is an electrically dreiven eccentric weight which induce the horizontal oscillation of the vibroflot. The vibroflot string is assembled with the vibroflot and extension tube to suit the improvement depth and suspended from a crane or mounted on a custom build base machine.

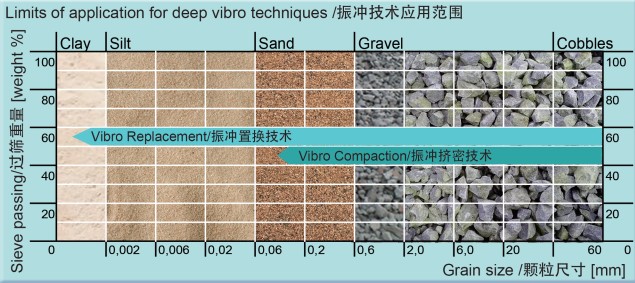

The vibroflot is used for 2 distinct techniques which deffer both in their soil improvement and in their load transfer mechanism.

The vibro compaction technique compacts granular soil with negligible fines content by rearrangement of the soil particles into a denser state.

The Vibro replacement technique builds load bearing columns made from gravel or crushed stones in cohesive soils and granular soils with high fine content.

The vibro techniques present a very versatile improvement method that can be adjusted to a wide variety of ground conditions and foundation requirements. Its execution is comparatively fast even if large volumes of soil are to be improved and subsequent structural works can follow very quickly. The soil improvement enables constructor to utilize standard shallow footings which, in turn, leads to additional savings. Another advantages is environmental friendliness of the vibroflot techniques. As natural and in situ materials are used. In addition, only a comparatively small quantity of soil is removed during process.

The vibro compaction of sandy soil is the technology of using the vibration load to rearrange the particles and reduce the volume and become dense sand.

For saturated soil, under the repeated horizontal vibration stress ,soil water pressure increases quickly, the connect force between soil particles decrease, and the soil particles are transferred to the lower potential energy, forming a tight stable structure to adapt to the new stress condition.

1) Vibration and extrusion: The horizontal vibration force of the vibroflot is transmitted through the soil skeleton to compact the surrounding soil.

2) Vibration float: Vibration cause the increase of water pressure in the surrounding soil, which leads to the destruction of the structure of the soil particles and formation of a new stable structure.

3) Consolidation: When the water pressure dissipates under the effect of stress on the sand soil, the consolidation is generated.

It is often used to improve the foundation of cohesive soil. It is to use the vibration and high pressure water shocking, forming the gravel pile in the foundation, so as to form a composite foundation bearing system with the foundation soil, to achieve the purpose of improvement.

1) Pile effect:The pile with higher strength can reduce the additional stress of the foundation soil through the stress concentration.

2) Cushion effect: The stress exerted by the foundation is not only passed down from top of the pile, but also through the lateral deformation of the pile body to the surrounding soil. The composite foundation is equivalent to a stiffened artificial cushion with better diffusion properties.

3) Drainage: The good drainage performance of the pile helps to consolidation the viscous soil with high moisture content, thus improving the strength of cohesive soil. At the same time, when the building load applied, the super-void water pressure generated in the foundation soil can dissipate rapidly, so that the consolidation settlement can be completed quickly.

1. Non-feed vibro compaction is suitable for: coarse sand, medium fine sand, coarse sand in gravel.

2. Feed vibro compaction is suitable for: fine sand, medium fine sand soil.

3. The vibroflotation replacement stone column is suitable for: soft clay with silty soil, general clay and undrained shear strength greater than 20KP.

4. Vibroflotation replacement stone column can be used for: miscellaneous soil, fly ash foundation and collapsible loess.

5. If the bottom feed method is adopted, the vibro displacement gravel pile can also be used for soft clay with less shear strength than 20KP.

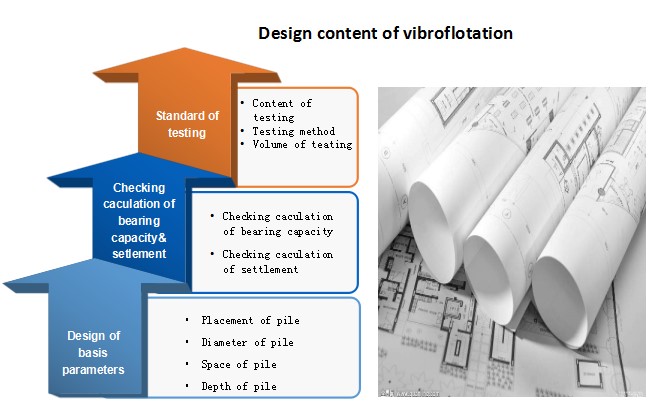

The design of vibro compaction method is mainly based on experiment and engineering practice.

Compaction depth:

The stress distribution and foundation soil strength can be determined according to the load of upper building.The formula of calculation is accorded to the standard of building foundation.

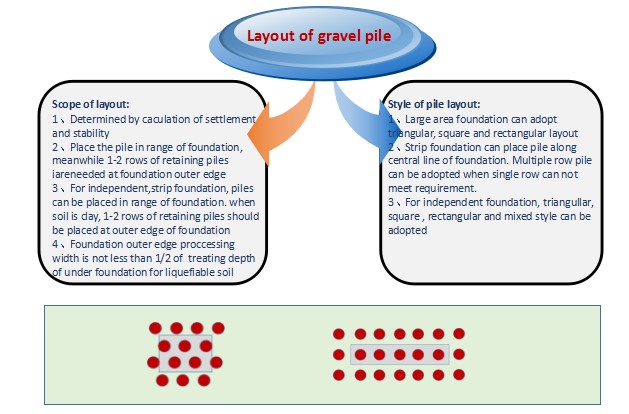

Compaction scope:

1) the strip foundation or independent foundation can only be used in the base range.

2) raft base and box base are usually piled on the whole foundation, and 1-3 rows of bollards can be arranged according to the need.

Space of piles and piling method:

A normal triangular or square style layout is generally adopted.There are several methods for pile spacing design:

1) field test method.

2) estimation of filling volume.

3) empirical formula method.

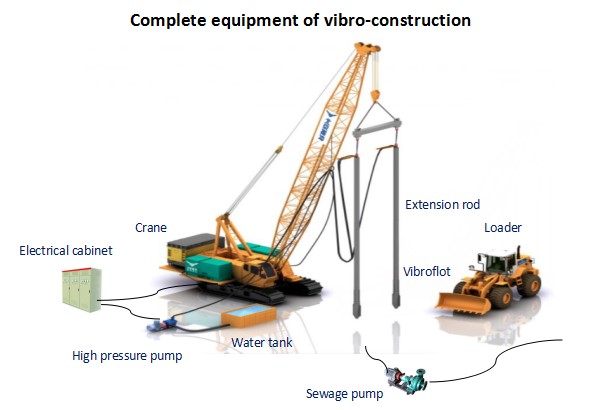

Complete equipment of vibroflot construction

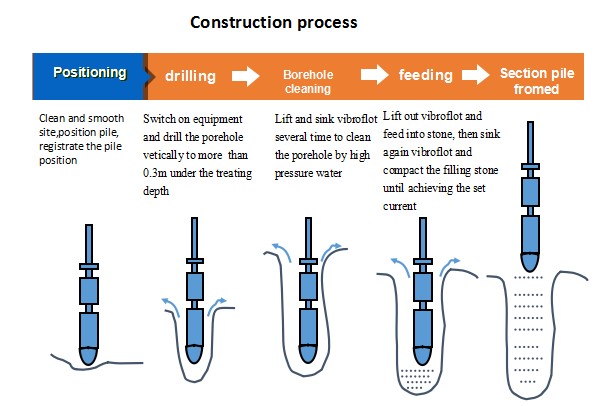

Vibroflot construction process

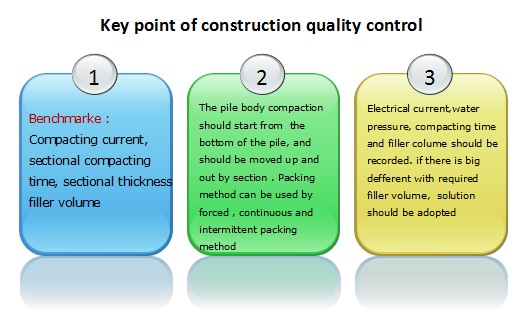

Vibroflot construction quality control

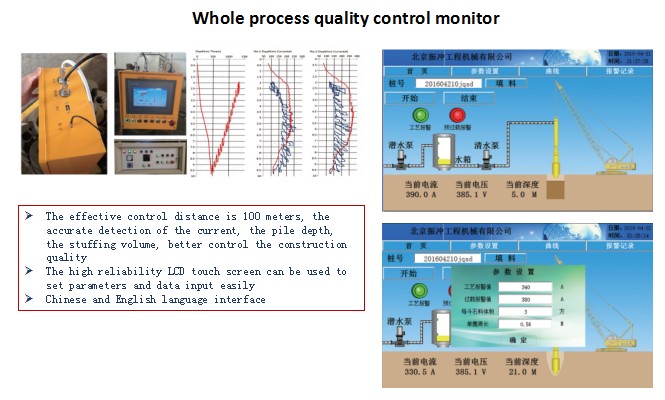

Vibroflot construction whole process quality control monitor